PETROLEUM COKE

PETROLEUM COKE

Petroleum coke, also known as petcoke, is a versatile and cost-effective source of energy and high-quality carbon. It is produced from the residual crude oil left over from oil refining, specifically in delayed coking units.

Petroleum coke, also known as petcoke, is a versatile and cost-effective source of energy and high-quality carbon. It is produced from the residual crude oil left over from oil refining, specifically in delayed coking units.

The quality of petroleum coke varies depending on its chemical properties, including sulfur, ash, and metal content, as well as its physical properties, such as structure, hardness, and size. Importantly, the quality of the petcoke produced at each refinery is heavily influenced by the specific feedstock used, primarily the type of crude oil that was distilled into vacuum residue in the vacuum column.

Petroleum coke has several classifications, with the most relevant referring to its main downstream applications or industries. At The International Center Company, we categorize petcoke into the following types:

1- Anode-grade petcoke, which is used for the production of anodes for aluminum smelters.

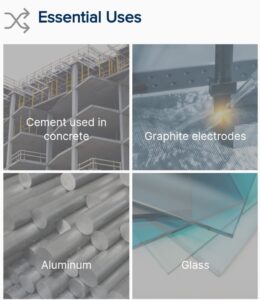

2- Fuel-grade petcoke, a solid fuel used in cement, glass, metallurgical, and other industries that require an inexpensive and efficient source of energy or carbon.

3- Specialty cokes, unique quality materials that are either specifically produced or specially treated. These cokes are supplied in tailor-made supply chain solutions.

Clients choose DYM Resources for their petcoke needs not just for the quality of our products, but also for our ability to deliver volume. Leveraging our expansive logistics network, we can export large quantities of petcoke across the eastern continents at competitive prices. Furthermore, we offer specific product adjustments based on a client’s specification, particularly in the calcined petcoke market. Our extensive research and market intelligence in this field are key to our success.

Types of Petroleum coke (Petcoke)

Green Petroleum Coke: A Versatile Solid Fuel for the Global Market.

Introduction

At The International Center For Import And Export, we specialize in providing high-quality Green Petroleum Coke (Green Petcoke), a foundational solid fuel used across a variety of industries. Extracted during the oil refining process, Green Petcoke serves as a critical raw material that, due to its high carbon content and calorific value, has become indispensable in both energy generation and metal production processes.

What is Green Petroleum Coke?

Green Petroleum Coke is a carbonaceous solid residue derived from the oil refining process. Unlike its calcined counterpart, Green Petcoke has not undergone the additional heating process to remove moisture and volatile compounds. This makes it a cost-effective and high-energy solid fuel option for various industrial applications, as well as a key input for further processing into Calcined Petcoke.

Applications and Advantages

Energy Production: As a solid fuel, Green Petcoke is utilized in cement and lime kilns, power plants, and other industrial boilers, offering a high heat and energy output that is essential for these energy-intensive processes.

Metal Industries: In the aluminum and steel industries, Green Petcoke is processed into Calcined Petcoke, a critical component in the production of anodes for smelting. Green petcoke is also used in silicon metal and ferroalloys production.

Solid Fuels Market: Beyond its industrial applications, Green Petcoke represents a significant portion of the solid fuels market, providing an economical and high-calorific value option for various heating and power generation needs.

Quality and Sustainability at DYM Resources

Our commitment to quality and sustainability is at the forefront of our Green Petcoke supply. We source our Green Petcoke from reputable providers to ensure that it meets the highest standards of purity, consistency, and environmental compliance. Our expert team works closely with clients to understand their specific needs, offering tailored solutions that optimize performance and efficiency.

Partner with Us for Your Green Petcoke Needs

Our Company is your trusted partner in the supply of Green Petroleum Coke. With our extensive experience and commitment to excellence, we are here to support your operations with premium solid fuels that drive efficiency and sustainability.

To learn more about our Green Petcoke solutions or to discuss your specific requirements, please Contact Us. Let us help you harness the power of one of the most versatile solid fuels available in the market today.

Comprehensive Applications of Petroleum Coke: Green and Calcined

Introduction

Petroleum Coke, in both its green and calcined forms, serves as a versatile material across a wide array of industries. At DYM Resources, we are committed to delivering high-quality Green Petcoke and Calcined Petcoke, each serving distinct purposes and applications. Below, we outline the primary uses of these materials, emphasizing their importance in today’s industrial landscape.

Green Petroleum Coke Applications

Green Petroleum Coke, known for its energy-rich composition and versatility, is primarily used as:

Solid Fuel : Leveraged in power generation and cement kilns, Green Petcoke offers a cost-effective and high calorific value alternative to traditional fossil fuels.

Feedstock for Calcination: Serving as a key raw material, it is calcined to produce Calcined Petcoke, used in various metallurgical processes.

Calcined Petroleum Coke Applications

Calcined Petroleum Coke is distinguished by its purity and the removal of volatile substances and moisture. Its applications include:

Aluminum Industry : As a critical component in the production of anodes, Calcined Petcoke is indispensable in the electrolytic process of aluminum smelting.

Steel Industry: Utilized as a recarburizer (carburizer) in steel manufacturing, it aids in achieving the desired carbon content in steel.

Battery Anodes : With the rise of electric vehicles and renewable energy storage solutions, both Green Petcoke and Calcined Petcoke play a pivotal role in the production of battery anode coke and electric battery anodes. This application underscores the material’s importance in the burgeoning energy transition sector.

Iron and Foundry Industry: Employed as a carburizer, it enhances the carbon content in iron casting processes, optimizing the quality and durability of the final products.

Grouped Applications Overview

Energy and Fuel: Green Petcoke serves as a solid fuel for energy generation, highlighting its role in the power and cement industries.

Metallurgical Processes : Calcined Petcoke is pivotal in aluminum and steel production, acting as an essential element in anodes and as a recarburizing agent, respectively.

Advanced Manufacturing: Both forms of Petcoke contribute to the production of battery anodes, marking a significant step towards sustainable energy solutions.

Foundry and Iron Industry: As a carburizer, Calcined Petcoke plays a crucial role in enhancing the carbon profile of cast iron and steel products

Calcined Petroleum Coke (CPC): A Keystone for the Aluminum Industry and Beyond

Introduction

Calcined Petroleum Coke (CPC) stands as a critical ingredient in the production of aluminum, serving as the primary raw material used in the anodes manufacturing process. Its role extends beyond the aluminum industry, contributing significantly to the steel and other carbon-consuming sectors. At dymresources.com, we specialize in the production and supply of high-grade CPC, tailored to meet the stringent specifications of our diverse clientele.

What is Calcined Petroleum Coke?

Calcined Petroleum Coke is derived from the process of calcining green petroleum coke (GPC), a by-product of oil refining. The process involves heating GPC at high temperatures, up to 1200 to 1350°C, to remove moisture, volatile matter, and impurities. This transformation results in a product that boasts a high carbon content, low sulfur levels, and minimal impurities, making it an ideal material for various industrial applications.

Applications of CPC coke

Aluminuium Production : CPC is indispensable in the production of aluminum. It is used to manufacture anodes, which are crucial for the electrolysis process that separates aluminum from its oxide.

Steel Industry: Employed as a recarburizing agent, CPC helps in adjusting carbon content to ensure the production of high-quality steel.

Graphite Electrode Manufacturing : Given its high purity and carbon content, CPC coke is also a key component in producing electrodes for electric arc furnaces in the steel industry.

Other Uses : Beyond these, CPC finds applications in titanium dioxide production, as a component in brake pads and clutches, and in the manufacturing of lithium-ion batteries.

Our CPC Product Range

Our CPC Product Range

At The International Center Company , our CPC portfolio is designed to cater to the specific needs of various industries. Our products are distinguished by their:

– High Carbon Purity: Ensuring efficient and clean production processes.

– Low Sulfur Content: Meeting environmental standards and reducing sulfur emissions.

– Optimal Particle Size Distribution: Tailored to enhance performance in its application.

– Quality Assurance and Sustainability.

We are committed to sustainability and stringent quality controls. Our CPC production is guided by an unwavering commitment to environmental stewardship and quality excellence. From sourcing the finest green petroleum coke to employing advanced calcining technologies, we ensure our CPC coke not only meets but exceeds industry standards.

Metals & mineral resource supply chain continuity:

Our competitive advantage is in risk management, financing, unique value sharing and long term strategic cooperation with the multiple upstream producer partners across Africa; this offers our customers from all over the world rare opportunity of guaranteed product availability throughout the year while at the same time optimizing scalability, flexibility and efficiency.

Metals and Mineral Resources

Copper

Iron Ore

Chrome

Manganese

Bauxite

Ilmenite

Calcium Carbonate

Refractory Metals

Rare Earth Metals